Competence and quality in mold design and construction

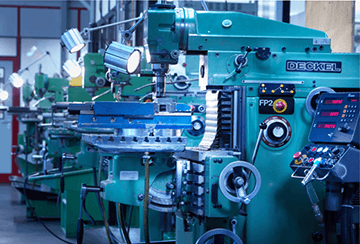

Since 2000, the name "MIDENA Elektrowerkzeugbau" has been standing for highest quality and precision. In this high-tech age, tool and mold design and construction are important items in the industrial value-added chain as connecting links between development and production. They are decisive for the costs, quality and time to market of new products to a significant degree. An optimum market strategy and constant adaptation of the products to customer requirements are indispensable for securing global competitiveness. Knowledge of the current market situation and updating own production processes are especially important. MIDENA faces the challenge of optimizing methods for the production of complex tools and moulds to meet the highest demands on industrial work processes with respect to economics and quality. We meet this demand by applying different CAD/CAM technologies as well as a high-tuned processing technology, for example 5-axis milling. The symbiosis of highly motivated experts, the most modern production facilities as well as the development of complex processing strategies makes it possible to design work procedures economically. In line with these demands, MIDENA is actively involved in the market with its services, today as well as tomorrow.

The Team

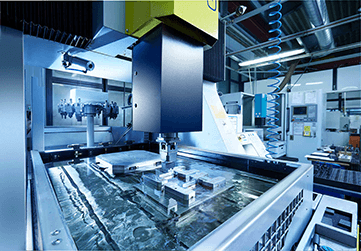

The long-standing practical experience of our coordinated team of experts and the most modern CNC machines guarantee the highest product quality in the production of injection moulds.The PPMS system by SEGONI ensures customer-oriented order processing and targeted schedule control. A reliable change and repair service rounds off our offer portfolio. Our capable team guarantees the fulfillment of the highest quality demands and the shortest processing times. The production of sliding split moulds using hot channel and multi-component technology is one of our strengths.

Internally trained junior employees in the field of precision mechanics will continue to secure our efficiency in the future as well.

Our focus

PPMS (production, process and management system)

SEGONI - PPMS is the IT tool for operational procedures in small and medium tool and mould construction companies. We have opted for SEGONI to ensure process-oriented organization and control of individual and small series productions. Technical and commercial data is administered in one system. SEGONI is a stable management software that non-IT specialists can also use effortlessly. It is applied in rough and detailed calculations for offer generation and also allows direct evaluation regarding capacity and schedule in case of order placement.

CIMATRON (3D-Systems)

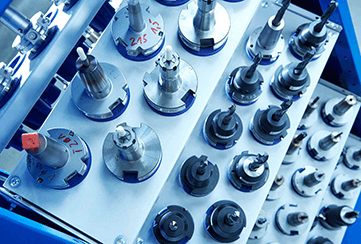

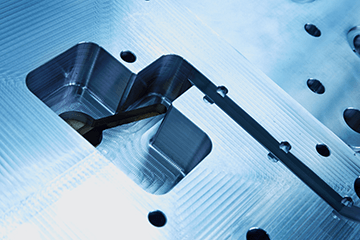

Our machines are programmed exclusively with software products from 3D Systems. We have been using Cimatron for many years for the entire electrode process, from derivation, documentation and NC programming to automatic output of the eroding parameters to the sinking EDM machines using EDM setup. All NC milling programs, from pocket machining to 3+2-axis milling and 5-axis simultaneous milling, are created with Cimatron NC. Additionally we can use Cimatron to make changes to your product data if required. For high-speed roughing we use the software extension VoluMill. In addition to the time savings offered by this module, we can use our manufacturing capacities much more flexibly. Thanks to the reduced spindle load, machines that do not appear to be suitable for roughing can be used for it, if necessary.

Sling split moulds

MIDENA manufactures sliders in the most varied designs: For use as undercut from the inside or the outside or as inner slides. Our slider tools demould undercuts with the aid of angle pins or slider cam plates with hydraulic or pneumatic cylinders. Furthermore available for undercutting: Split cores tensioned or relaxed through wedge effect, as well as collapsible cores. Combinations of sliders and collapsible cores, e.g. in the field of demoulding threads without thread cutting units are also available. Complex unscrewing tools with transmission units are manufactured according to customer specifications. Collapsible cores as prefabricated units by renowned manufacturers can be integrated in the moulds. Screw cores and/or screw sockets are being used that release the threads on the mould during the demoulding process. They can be driven by the opening motion of the tool like high-helix lead screws, racks, etc. or via special unscrewing units.

Repairs

Here we distinguish between: repair, modification and maintenance orders. The so-called emergency repairs are a special kind of repair orders. Failure of the mould during the current production process may result in long downtimes and high costs. This is where our specialized team comes in. We offer on-site service for smaller repairs. In case of larger repairs, the moulds are delivered. A hall crane and various lifting equipment is available for immediate dismantling. Afterwards, we perform an immediate damage analysis and define the further procedure while informing the customer at the same time. Orders are handled and completed with top priority using the possibilities of laser welding and different repair coating types like e.g. external chemical solid nickel plating. Injection moulding machines produce in increasingly shorter cycles. This is why it is indispensable to have moulds serviced regularly by expert personnel. Damaged components are already exchanged beforehand. Here it is also possible to benefit from the advantages of the PPMS system, because all work performed on the mould is saved. The maintenance history of each tool can be traced over years.

The moulds we manufacture can be sampled at our parent company, MENNEKES Elektrotechnik GmbH & Co. KG, with its approx. 40 different injection moulding machines. Injection moulding tools with a weight of up to three tons can be realized by our tool design and construction department.

The CNC electric discharge machining system by OPS/INGERSOLL and the CNC electric discharge wire cutting systems by AGIE/CHARMILLES and MITSUBISHI ensure the finest details.

Our tool design and construction department uses the 3D or 2D data or item drawings you have supplied as template. We can manufacture your most complex items with the Cimatron and ProE systems. All programming stations and CNC machines are networked.

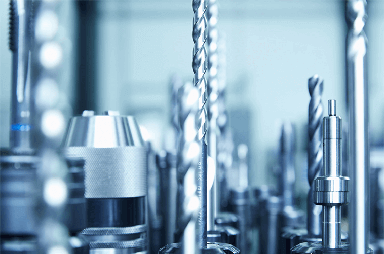

The modern HSC technology allows processing of graphite electrodes or hardened steel parts without problems. The processing centers of DMG or OPS/INGERSOLL assist us with the production of your precise 3D contours.

A CNC, an NC and a universal lathe are used in our production department. The CNC-controlled machine is a DMG CTX 400, the NC machine a Boehringer DUS 560. These machines enable us to manufacture individual precision parts and small series.