X-CONTACT: innovative, simple, durable and safe

Contact sleeves account for the quality of our contact closures in all of our connectors and receptacles. We combine easy handling and secure contact closures thanks to our X-CONTACT technology. It is implemented in every connector of our PowerTOP® Xtra range from 16 to 125 A, in our wall mounted receptacle DUO, our wall-mounted and plate mounted receptacles as well as the respective receptacles in our combinations.

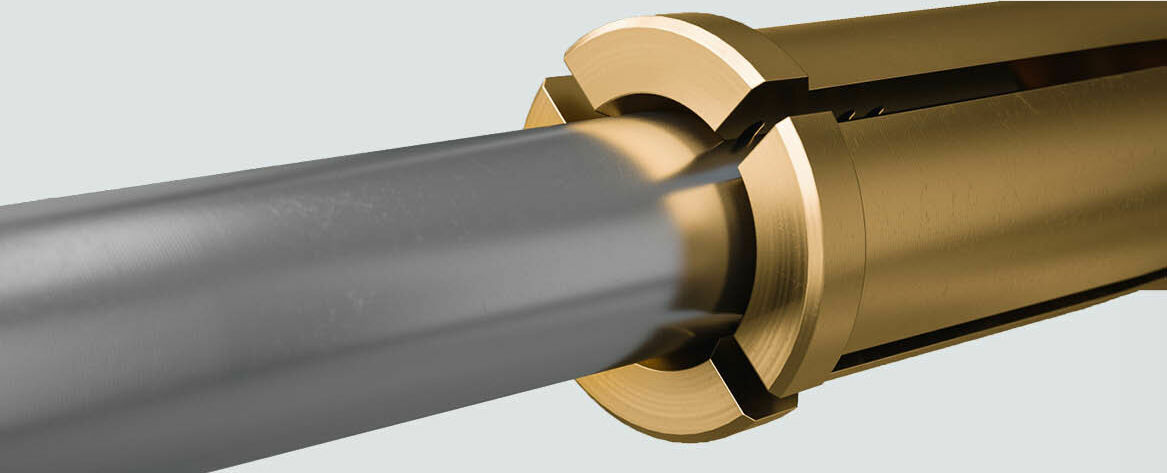

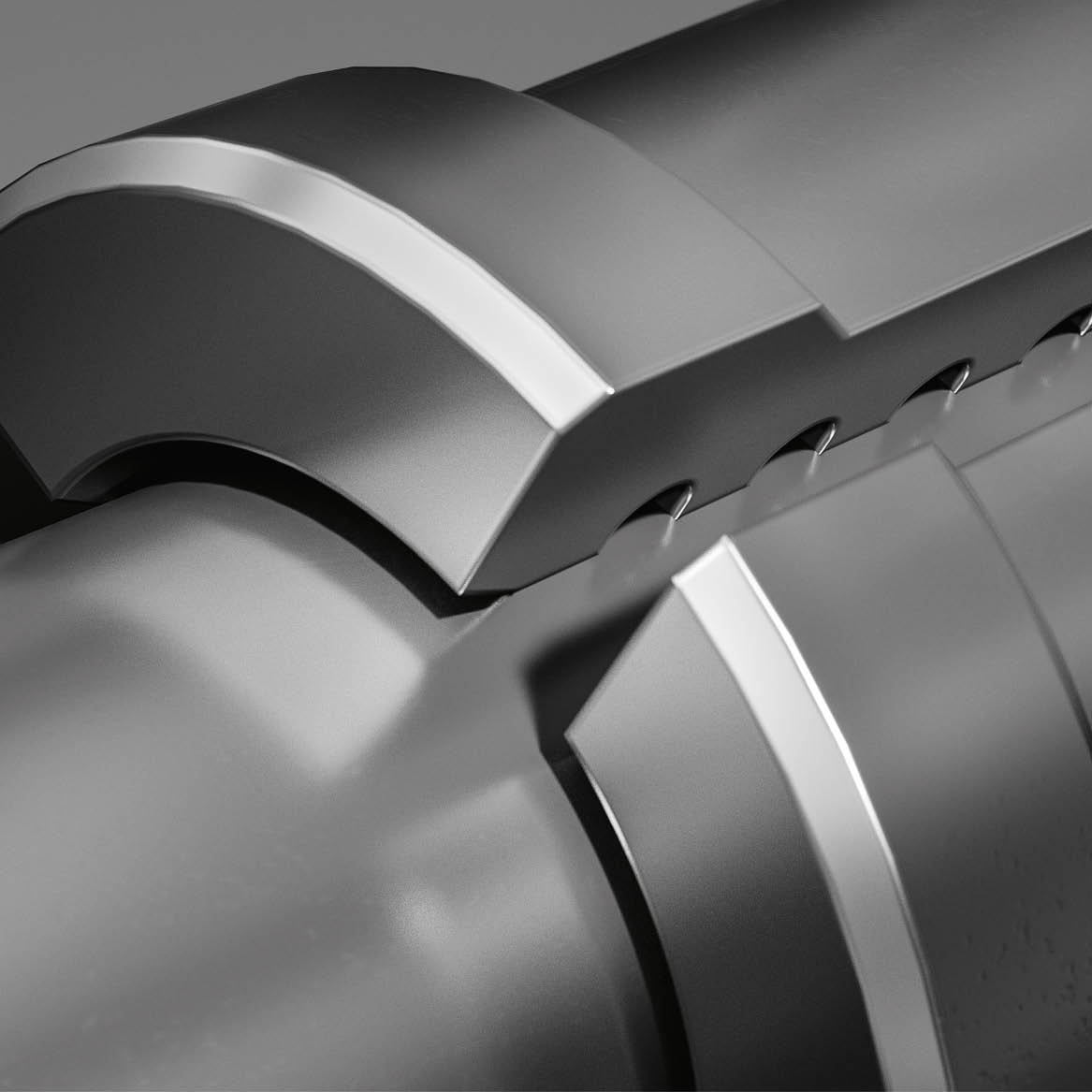

Due to a completely new manufacturing process, the X-CONTACT sleeve obtains resilient properties based solely on its material characteristics, without the need to use any additional spring elements. Thanks to the shape of the X-CONTACT sleeve, a particularly safe contact closure can be achieved.

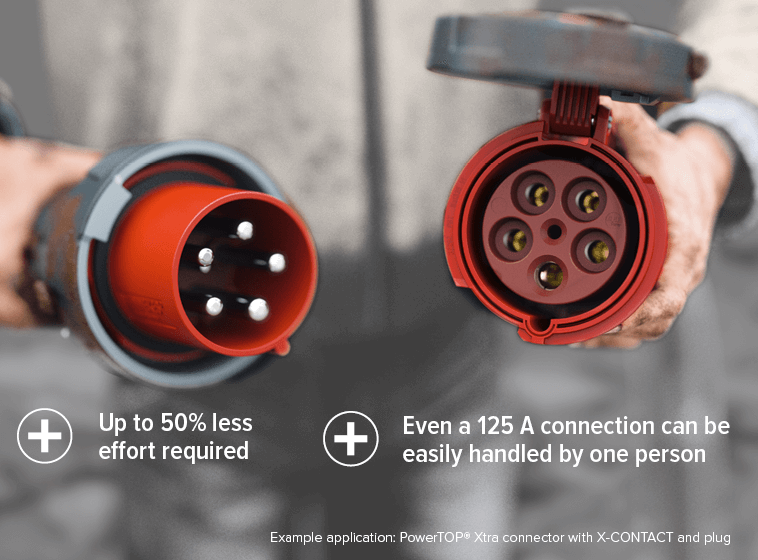

The special design of the X-CONTACT reduces the effort of insertion and withdrawal by up to 50%. An advantage that simplifies work processes and improves safety especially with high electrical currents. With X-CONTACT, MENNEKES creates a safe contact closure and easy handling at a new, equally high level.

But how does X-CONTACT achieve these benefits even with currents of 63 A or 125 A? A glance into the opening of an X-CONTACT sleeve reveals the intelligent functional principle: the X-shaped slot and groove in the inner wall provides four advantages of the new design: innovative, simple, durable and safe. We call it the X principle.

The X principle: Easy handling meets safe connections.

Innovative

Due to the slotted sleeves with their resilient material properties, X-CONTACT is the simplest possible mechanical solution: the plug pin simply expands the opening of the resilient contact sleeve, which reduces the force needed to connect and disconnect the plug by up to 50%.

X-CONTACT – intelligently innovative!

Simple

In practice, X-CONTACT simplifies work processes. The connection is easier to handle when compared to convenient contact sleeves.

X-CONTACT – simply brilliant!

Durable

Even in cases when the plug is connected and disconnected frequently, there are no signs of wear and the sleeve material remains fatigue-proof in the long term even after rough handling. Due to the quality of the new sleeves, contamination and surface corrosion is automatically removed by connecting and disconnecting.

X-CONTACT – lasting solution!

Safe

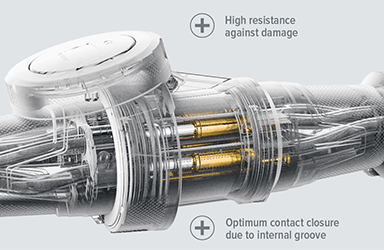

A higher degree of safety of handling is provided by the easier connection and disconnection. The groove within the inner wall in connection with the resilient material of the contact sleeves provides for a safe contact closure.

X-CONTACT – double safety!

Improved handling.

Particularly with currents of 125 A or 63 A, the forces required to connect and disconnect a conventional plug are very high. Those connections are often rough-running that two persons are needed to disconnect. This not only disturbs the work process but is also a potential hazard.

Particularly in industrial applications, plugs and sockets have to be robust, but at the same time also simplify all processes as well as make them practical and safe.

X-CONTACT is perfectly suited for these requirements. The slotted X-CONTACT sleeves ensure noticeably smooth handling of the plug pins, without the need to overcome high resistance. The required insertion and pulling forces are reduced by up to 50% compared to conventional contact sleeves.

At the same time, the simplicity of the X-CONTACT sleeve is in its design and construction to withstand rough handling. This ensures easy handling of X-CONTACT and you do not need to worry about a safe, constant contact closure for a long time, because these X-CONTACT advantages are sustainable due to the wear resistance of the sleeves.

Less force

The innovative manufacturing process and the material used ensure the elasticity of the sleeve. As a result, the force needed to connect and disconnect the plug is reduced by up to 50%. This can now be handled by one person – even a 125 A connection!

Slot

The top view of the sleeve shows the opening, which due to the slot will be expanded by the plug pin. An effect that is only possible with this new MENNEKES innovation.

Resilient material

The plug pin expands the resilient sleeve opening when it is inserted.

Enormous strength and contact durability.

Conventional connectors for currents of 63 A or 125 A have always been a compromise between simple handling and contact quality. Easy handling was only possible where contact quality was compromised, and vice versa. Due to the physical conditions, this dilemma seemed to be inevitable. Due to the high requirements on the temperature resistance and the smooth insertion process in the automotive sector, we have achieved a higher quality of contact, and transfer it now from our automotive development to industrial applications. What is already established in the e-mobility industry, is now also used in our industrial plugs and sockets. In addition to the high-quality manufacturing technology, there is also a second important shape factor:

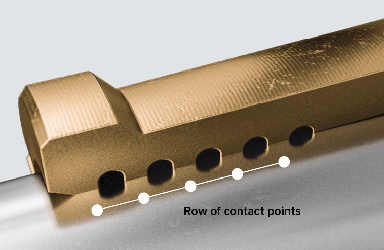

The inner walls of the slotted X-CONTACT sleeves have grooves perpendicular to the connection direction. The resilient material connects with this internal groove to form a highly flexible contact closure. Even with rough handling – in practice, the rule rather than the exception – slot, resilient material and groove together provide a safe contact in every situation.

A slight angle, which is almost always present in the connection of plug and connector, thanks to the X-CONTACT design, can in no way damage the sleeves. In addition, the connection of the resilient material and the grooved inner wall always forms a row of contact points. Even insertion and pulling of the plug under load does not reduce contact quality in connectors with X-CONTACT.

At a second glance

If you look into the connector or the receptacle from the outside, you will see that they are provided with X-CONTACT sleeves.

Grooves and slots

The grooves also ensure the optimal contact, even if the plug is inserted with a slanted angle.

Grooves inside

They optimally complement the resilient material to achieve more contact and less force at the same time. Always – even when connecting and disconnecting the plug under load.

Reliable even under the toughest conditions.

Innovative, simple, durable and safe – the X principle is not a promise, it’s a fact. But it is even better because X-CONTACT sleeves withstand the toughest conditions due to their simple, brilliant functional principle.

The interaction of the resilient material and groove is not only the guarantee for a secure contact closure, it also has the practical side effect that any contamination is removed when connecting and disconnecting the plug. Even surface corrosion is removed by the spring effect of the X-CONTACT sleeves.

For particularly corrosive environments – such as irritant chemical substances like ammonia – we offer the nickelplated contact sleeves with all their advantages.

Contamination

All deposits are removed from the pin by the grooves of the contact sleeve. This ensures a sustainable smooth operation under the toughest conditions.

Nickel plating

Connectors and receptacles with nickel-plated contact sleeves ensure maximum resistance in aggressive environments. They withstand humidity, salty or acidic air and aggressive gases and vapours.

Resistant

The cleaning effect of the grooves ensures reliable operational safety due to low contact heating even with high currents and strong contamination.

X-CONTACT: Innovation inside

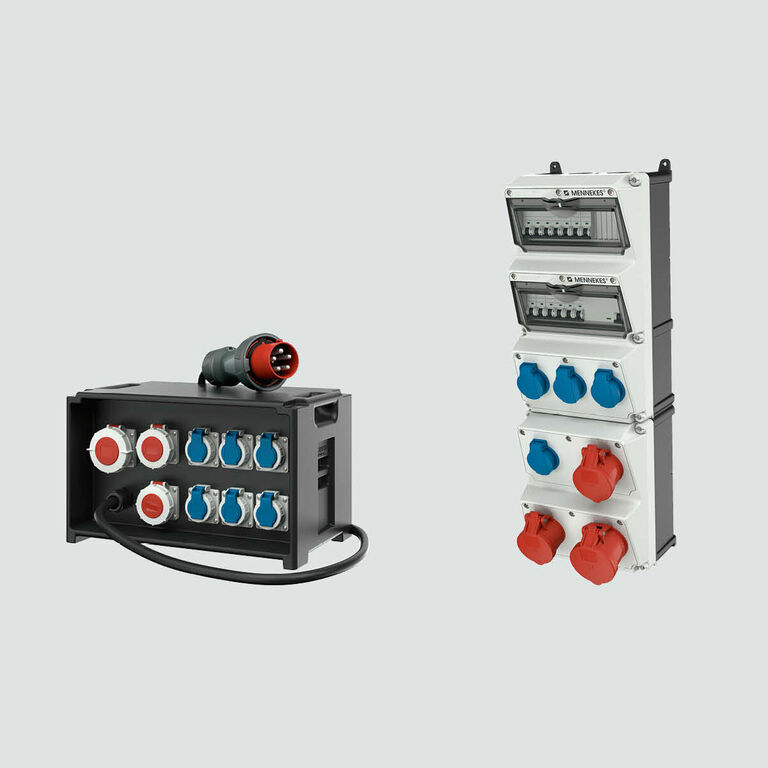

With X-CONTACT we set the standard for all industrial connectors and receptacles. For this reason we have implemented this new technological design in our entire product range. In future, all MENNEKES connectors and receptacles for currents of 63 A and 125 A and the PowerTOP® Xtra connectors 16 A and 32 A will have an X-CONTACT, this means that you will benefit from the advantages of the X-CONTACT in all applications. This applies to all versions of the following product groups: