Stable power supply for shipyards

- robust, durable materials for extreme conditions

- flexibly configurable distributors and combinations

- fast and safe installation, operation, and maintenance

- permanently installable and mobile products

- protected from dust and water

- if wished, combinations and receptacles made of special plastic (e.g. to protect against saline seawater) are available

- special solutions for special requirements

Welding, screwing, grinding, drilling, and sawing: building and repairing ships and yachts are complex, demanding tasks that involve many steps. In shipyards and at docks, many different work together, sometimes shoulder-to-shoulder in tight quarters and sometimes and across large distances. Each and every operation must be precisely executed; machines and materials have to be securely and safely operated and moved. This calls for electric power, which must be safely and reliably distributed via mobile and/or stationary gear. Whether you're a production foreman, maintenance manager, or planner, you can count on getting the right solution for your needs from us.

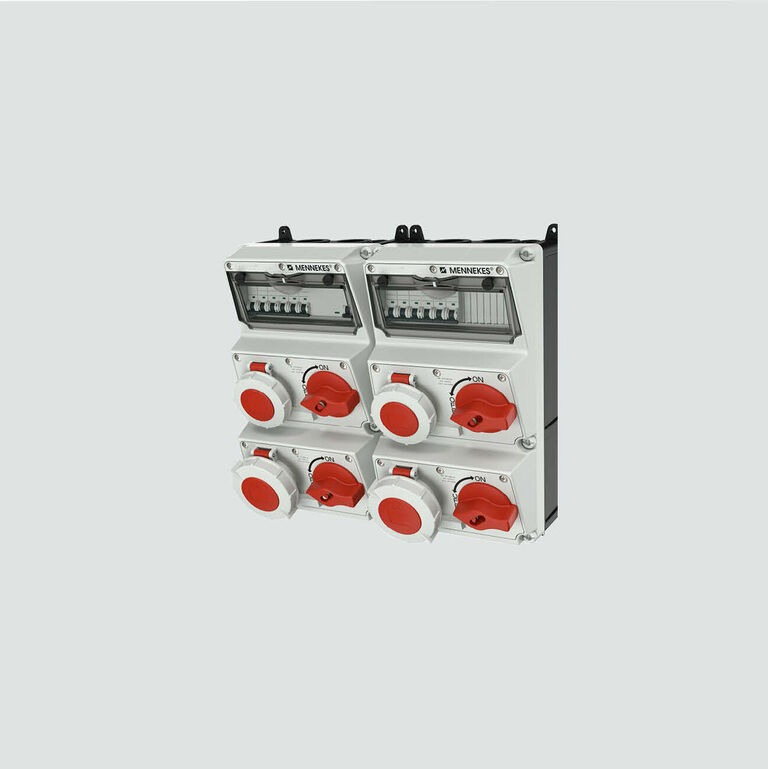

Receptacle combinations for shipyards

Our AMAXX combination units for wall mounted combination units are space-saving and flexibly configurable, letting them be easily deployed at many different places within a shipyard. Thanks to their intelligently designed features, they are quick and easy to install by a single person. The standard versions of the AMAXX products are made of robust plastic, or on request of a special enhanced plastic that affords extra protection from aggressive substances such as saltwater. These combinations feature IP44 or IP67 ingress protection and are therefore highly resistant to penetration by dust and water.

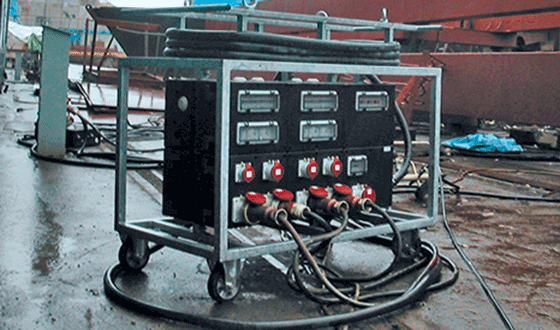

The mobile distributors of our EverGUM, EverBOX, and AMAXX product families feature a compact design, practical handles, and low weight. They are space-saving, easy to carry, and stackable. We originally developed the EverBOX Grip at the request of a customer in the shipbuilding industry before launching it as part of our range of standard products. The EverGUM comes in robust solid rubber while the EverBOX and AMAXX are made of plastic. Both materials are extremely impact-resistant and break-proof. The EverGUM has IP44 ingress protection and EverBOX IP44 or IP67, which effectively keeps out dust and water.

Our EverBOX products also include additional functions. They can be configured for 16 to 125 A, and a housing frame and handles provide extra protection for receptacles and connected equipment. The fuses are plainly visible behind transparent caps where they are very easy to access and change.

We'll be happy to build customized versions for you on request, for example of our inspection trolleys. The Meyer Werft shipbuilding company, among others, relies on them. This product can be carried by a crane and is equipped with rollers for mobility. It includes a sturdy steel frame, can be flexibly equipped with various receptacles on both sides, and includes a main switch, a socket for a feeder line, and eyes for being picked up and moved by a crane.

Receptacles for shipyards and the shipbuilding industry

Our portfolio of wall mounted receptacles for shipyards includes classic models, versions protected by fuse sockets or circuit breakers, and our switchable and mechanically lockable DUO range. The contact screws of these products are easy to access from the front. Our X-CONTACT contact sleeve technology can be integrated on request. This also makes it especially easy for you to insert and withdraw plugs when using high currents, requiring as much as 50% less force. The receptacles are made of high-quality plastic. These products are also optionally available made of special plastic and equipped with highly heat resistant contact carrier and nickel-plated contacts.

On request, we'll be happy to develop and produce customized versions, like our special, highly versatile wall mounted combinations. We assemble these modular products to meet your particular needs; they can be equipped with a wide range of switching devices and connections, among other things.

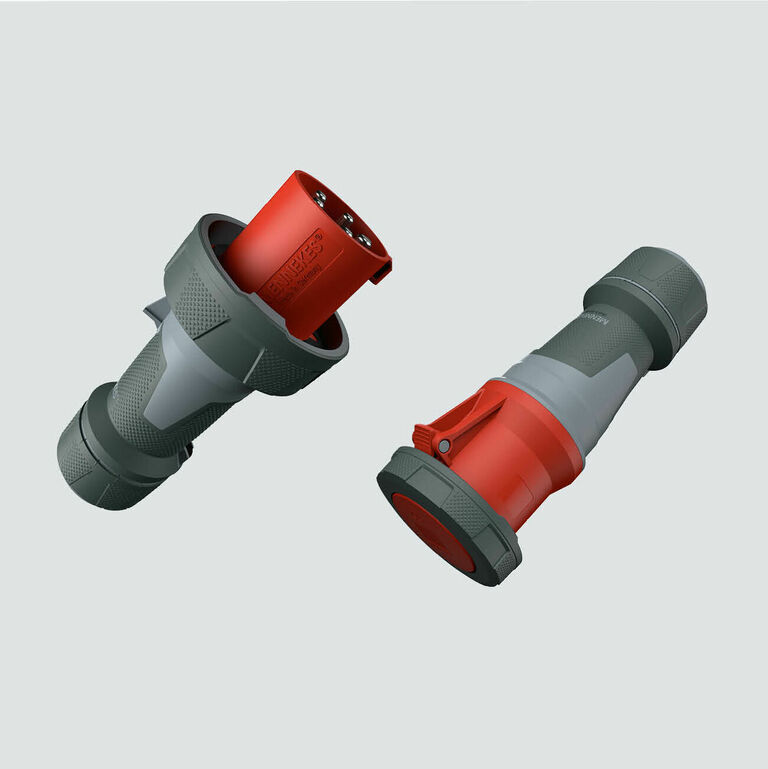

Plugs and sockets for shipyards and shipbuilding

Our PowerTOP® Xtra plugs and sockets help you flexibly and safely distribute power at shipyards. Ergonomically optimised design, nubbed grip zones, rubberised nubbed cable glands, an easy-open hinged cover, and locking sliders combine to ensure that plugs and couplings are easy to grip, lie in the hand perfectly without slipping, even when moist or wet, and have a lifetime of several thousand mating cycles.

These plugs and sockets are made of robust, long-lived materials and are available with IP44, 54, and 67 ingress protection. This means that they are optimally protected from dust and water. The PowerTOP® Xtra connectors for 63 A and 125 A feature highly heat resistant contact carrier and are optionally available with nickel-plated contacts. The plugs also have nickel-plated contacts. The five-pole plugs and sockets for 16 A and 32 A are also available in a PowerTOP® Xtra R version with the same robust features. This ideally protects them from aggressive substances. All of them boast our strength-saving X-CONTACT contact sleeve technology. Ingeniously designed connections make them quick and easy to install using a minimum of tools.